Detailed content

Technical Specifications

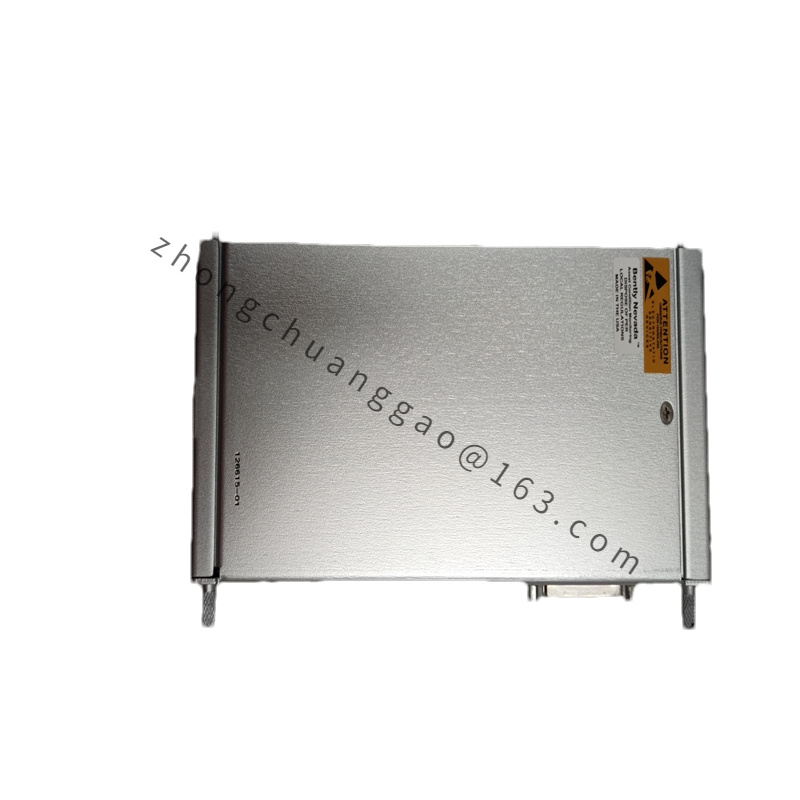

- Model: 190065A

- Type: Proximity Probe Extension Cable

- Function: Designed to extend the reach of proximity probes in machinery monitoring systems, facilitating their connection to the monitoring equipment.

- Cable Specifications:

- Length: Typically available in various lengths to suit different installation needs. For exact lengths, refer to the product datasheet.

- Conductor Type: Uses shielded twisted pair conductors to ensure signal integrity and minimize interference.

- Shielding: Includes robust shielding to protect against electromagnetic interference (EMI) and ensure accurate signal transmission.

- Electrical Characteristics:

- Voltage Rating: Rated to handle the standard voltage levels used in proximity probe systems. Specific ratings are detailed in the datasheet.

- Impedance: Matches the impedance of the connected proximity probes to ensure accurate signal transmission.

- Environmental Conditions:

- Temperature Range: Operates effectively within an industrial temperature range, typically from -40 to 85°C.

- Relative Humidity: Suitable for environments with relative humidity up to 95% (non-condensing).

Features

- Reliable Signal Transmission: Ensures accurate transmission of signals from proximity probes to monitoring systems, crucial for maintaining data quality.

- Durable and Robust: Designed to withstand harsh industrial conditions, including high temperatures and mechanical stresses.

- Effective Shielding: Provides shielding to minimize the impact of electromagnetic interference, ensuring stable and accurate signal transmission.

- Flexible Installation: Facilitates the connection of proximity probes to monitoring equipment over various distances, allowing for flexible probe placement.

- Compatibility: Specifically designed for use with Bently Nevada’s proximity probes and related monitoring systems.

Application Scenarios

- Machinery Protection: Used in machinery protection systems to connect proximity probes to monitoring systems, allowing for precise monitoring of rotating machinery components like shafts and bearings.

- Condition Monitoring: Applied in condition monitoring setups to extend the connection between probes and data acquisition systems, enabling continuous assessment of machinery health.

- Industrial Automation: Ideal for use in industrial automation systems where accurate signal transmission is essential for maintaining system reliability and performance.

- Process Control: Useful in process control environments to ensure reliable connections between sensors and monitoring systems, helping to maintain stable operation of machinery.

Installation and Configuration

- Mounting:

- Form Factor: Typically installed and routed in industrial environments to connect proximity probes with monitoring systems. Proper routing and installation are essential to ensure signal integrity.

- Wiring:

- Connections: Connects to proximity probes and monitoring systems using standard industrial wiring practices. Detailed installation and wiring instructions are provided in the product documentation.

- Configuration:

- Compatibility: Ensure the extension cable is compatible with the specific proximity probes and monitoring equipment in use. Configuration involves proper connection and routing to maintain system functionality.