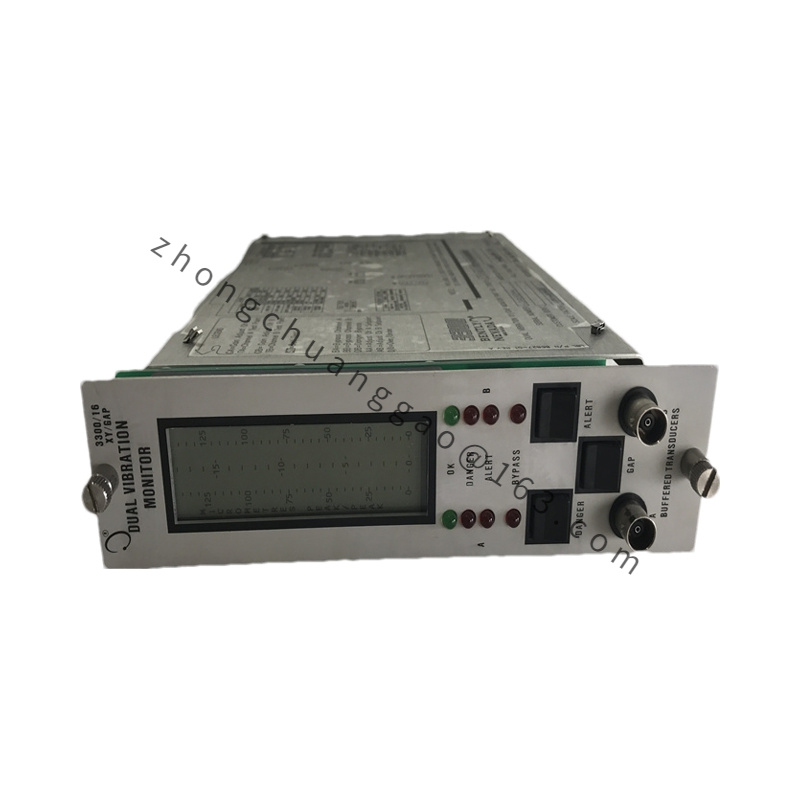

Bently 149992-01

The Bently 149992-01 is a part of Bently Nevada’s extensive range of machinery protection and condition monitoring systems. This specific model is designed to provide accurate and reliable measurements to monitor the condition of industrial machinery, helping prevent unexpected failures and optimizing performance.

Detailed content

Technical Specifications

- Type: Vibration Transducer or Sensor.

- Model: 149992-01.

- Sensor Type: Typically a piezoelectric accelerometer or similar type of vibration sensing technology.

- Measurement Range: Designed to measure a broad spectrum of vibration frequencies and amplitudes.

- Sensitivity: High sensitivity to detect small changes and anomalies in vibration.

- Output Type: Usually provides an analog output, such as voltage or current signals, compatible with industrial control and monitoring systems.

- Power Supply: Operates on standard industrial power supplies; specific details are available in the product datasheet.

- Temperature Range: Built to operate effectively within a specified temperature range suitable for industrial environments.

Features

- High Precision: Provides accurate vibration measurements for effective monitoring of machinery conditions.

- Durable Construction: Designed to withstand harsh industrial conditions, including extreme temperatures and mechanical stresses.

- Ease of Integration: Can be easily integrated with existing control and monitoring systems for streamlined operation.

- Advanced Diagnostics: Offers diagnostic capabilities to aid in identifying machinery issues and ensuring reliable performance.

- Robust Performance: Maintains consistent performance even in challenging industrial environments.

Applications

- Industrial Machinery Monitoring: Used for continuous monitoring of industrial machinery to detect and prevent unexpected failures.

- Condition-Based Maintenance: Supports maintenance strategies based on the real-time condition of machinery as indicated by vibration data.

- Predictive Maintenance: Helps in predicting potential machinery failures before they occur, allowing for preemptive maintenance actions.

- Process Optimization: Assists in optimizing machinery performance through detailed vibration analysis and diagnostics.