Detailed content

Technical Specifications

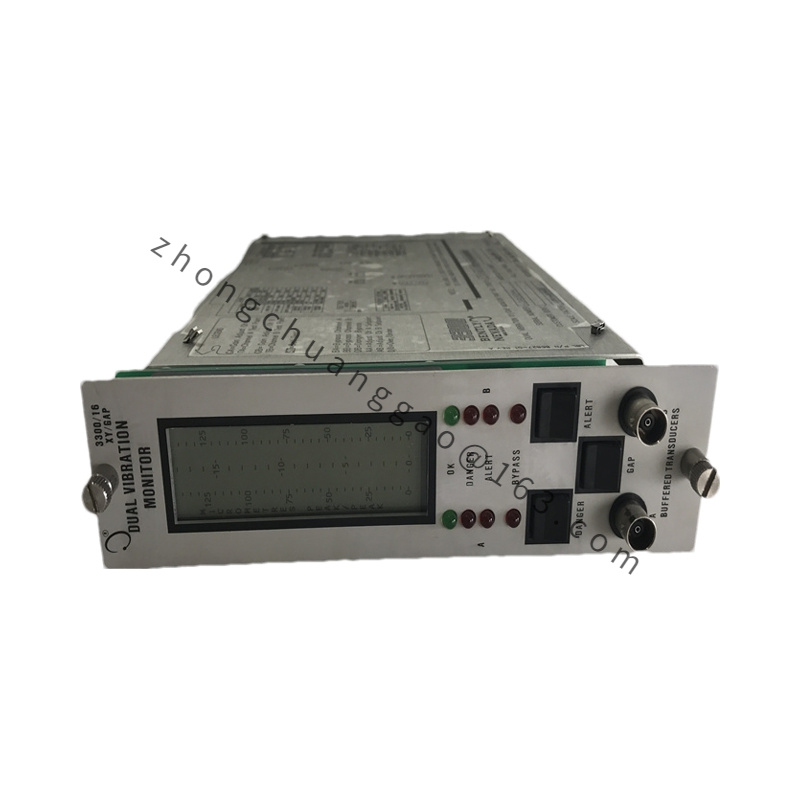

- Model: 106M1081-01

- Type: Vibration Monitoring System Module

- Function: Provides vibration monitoring and protection for rotating machinery.

- Measurement Capabilities:

- Sensor Compatibility: Interfaces with vibration sensors, such as accelerometers and proximity probes.

- Measurement Range: Capable of measuring a wide range of vibration frequencies and amplitudes. Specific ranges and limits should be confirmed with the product datasheet.

- Signal Processing:

- Data Acquisition: Handles acquisition of vibration signals, including necessary filtering and amplification.

- Signal Conditioning: Features integrated signal conditioning to ensure accurate data processing.

- Output Signals:

- Analog Outputs: Provides output signals, such as 4-20mA or voltage signals, for integration with other control and monitoring systems.

- Digital Communication: Supports digital communication protocols for enhanced system integration.

- Power Supply:

- Voltage Range: Operates with standard industrial power supply voltages. Exact voltage requirements are specified in the product datasheet.

- Operating Conditions:

- Temperature Range: Typically operates within an industrial temperature range of 0 to 60°C.

- Relative Humidity: Designed for environments with relative humidity up to 95% (non-condensing).

Features

- High-Precision Vibration Monitoring: Provides accurate and reliable vibration measurements to detect and diagnose machinery issues.

- Durable and Robust: Engineered for durability and reliability in harsh industrial environments.

- Versatile Sensor Interface: Compatible with a variety of vibration sensors, allowing flexibility in monitoring different types of machinery.

- Integrated Signal Conditioning: Includes signal conditioning features to ensure accurate and effective measurement of vibration signals.

- Comprehensive Integration: Designed to integrate seamlessly with Bently Nevada’s other monitoring systems as well as third-party systems, providing comprehensive condition monitoring solutions.

Application Scenarios

- Machinery Protection: Used in systems to protect machinery by monitoring vibration levels and identifying potential issues such as imbalances, misalignments, or bearing failures.

- Condition Monitoring: Applied in condition monitoring systems for continuous assessment of machinery health, enabling predictive maintenance and reducing unexpected downtimes.

- Industrial Automation: Ideal for integration into industrial automation systems where accurate vibration monitoring is critical to maintaining equipment reliability and performance.

- Process Control: Useful in process control environments where the health of machinery is crucial for ensuring operational efficiency and safety.

Installation and Configuration

- Mounting:

- Form Factor: Typically installed in control panels or industrial enclosures. Proper installation is essential for ensuring optimal performance.

- Wiring:

- Connections: Connects to vibration sensors and power supplies using standard industrial wiring practices. Detailed wiring diagrams and instructions are provided in the product manual.

- Configuration:

- Software: Configuration and setup are managed using Bently Nevada’s software tools, which allow users to configure measurement parameters and integrate the module with other systems.