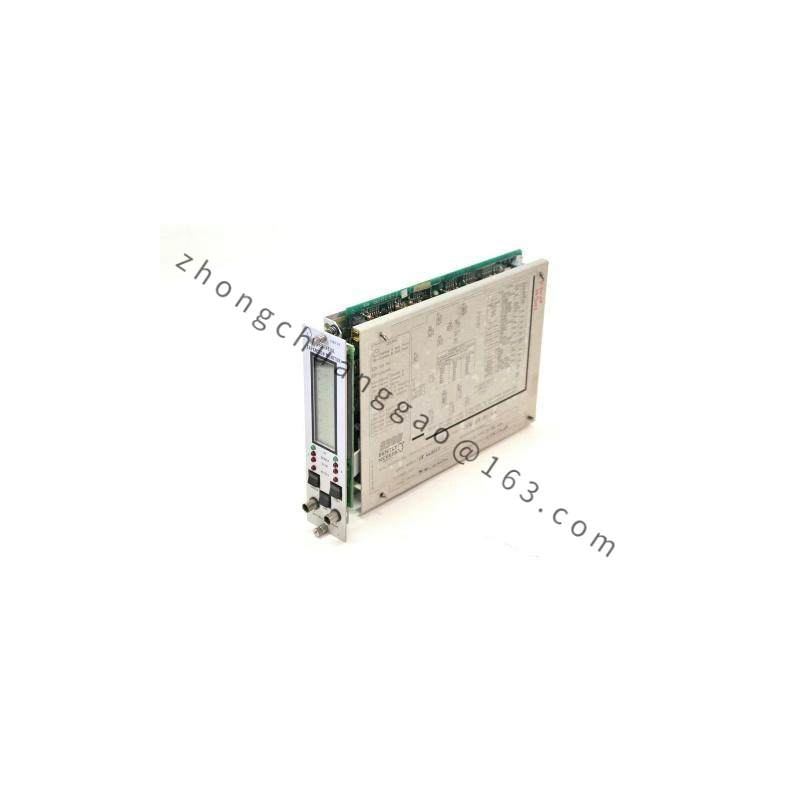

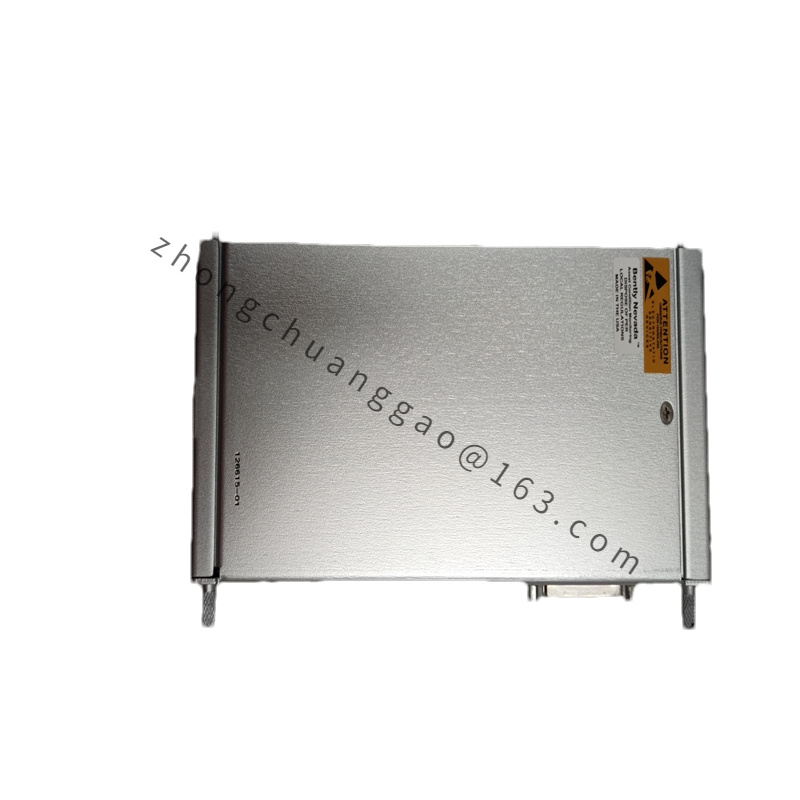

Bentley Nevada 3300/45 Differential Expansion Monitor, Precision Machinery Protection Solution

The Bently Nevada 3300/45 Differential Expansion Monitor is an advanced monitoring solution designed to detect and report on the differential expansion between two points on rotating machinery. Ideal for applications in power generation, petrochemicals, and manufacturing industries, it ensures operational safety and efficiency by providing real-time data on machine health.

Detailed content

Model:3300/45

Type:Differential Expansion Monitor

Brand:Bentley Nevada

Module Type:PLC

Designation:API 670 compliant

Instrument Rack Compatibility:Yes

Power Supply:AC or DC

Monitoring Functionality:Customizable modules

Operating Range:Broad temperature and pressure conditions

Accuracy:+/- 0.01% of full scale

Alerts & Outputs:Multiple configurable alerts and outputs

Maintenance Interval:Extended, based on usage

Certification:ISO 9001, CE marked

The Bently Nevada 3300/45 Differential Expansion Monitor leverages advanced capacitive sensing technology to deliver unparalleled precision in measuring minute dimensional changes in industrial machinery. Its robust design withstands extreme temperatures and harsh environments, making it ideal for use in demanding industrial settings.

Equipped with an intuitive RS-485 communication interface, this monitor seamlessly integrates into existing control systems, offering reliable data transmission and easy configuration. Its low power consumption ensures minimal impact on the overall energy efficiency of your operation.

Featuring an IP67-rated enclosure, the monitor is protected against dust and water ingress, ensuring uninterrupted operation even in dusty workshops or wet environments. Its compatibility with various shaft diameters guarantees a versatile fit across different machinery types, enhancing its utility across diverse industries.

With an accuracy of +/- 0.02% Full Scale, the Bently Nevada 3300/45 ensures precise monitoring, enabling early detection of potential issues before they escalate into costly downtime or equipment damage. This proactive approach to maintenance minimizes disruptions and maximizes productivity.

Designed for long-term reliability, the monitor undergoes rigorous testing to ensure durability and performance over extended periods. Its comprehensive feature set and ease of integration make it a valuable addition to any industrial control system, driving efficiency and safety in manufacturing processes.