Digital guide

You are here:

- Home

- Other brands

- BENDER RCM475LY-7113

Detailed content

Technical Specifications

- Monitoring Functions:

- Insulation Monitoring: Measures the insulation resistance of electrical systems.

- Leakage Current Monitoring: Detects leakage currents and ground faults.

- Earth Fault Monitoring: Monitors for earth faults in electrical installations.

- Input/Output:

- Measurement Range: Supports a wide range of insulation resistance values.

- Output Relays: Equipped with relay outputs for fault alarms or system disconnection.

- Communication Interfaces: Includes communication options for integration into control systems.

- Power Supply:

- Typical Input: 24V DC, providing flexibility for various installations.

- Power Consumption: Low power consumption to enhance operational efficiency.

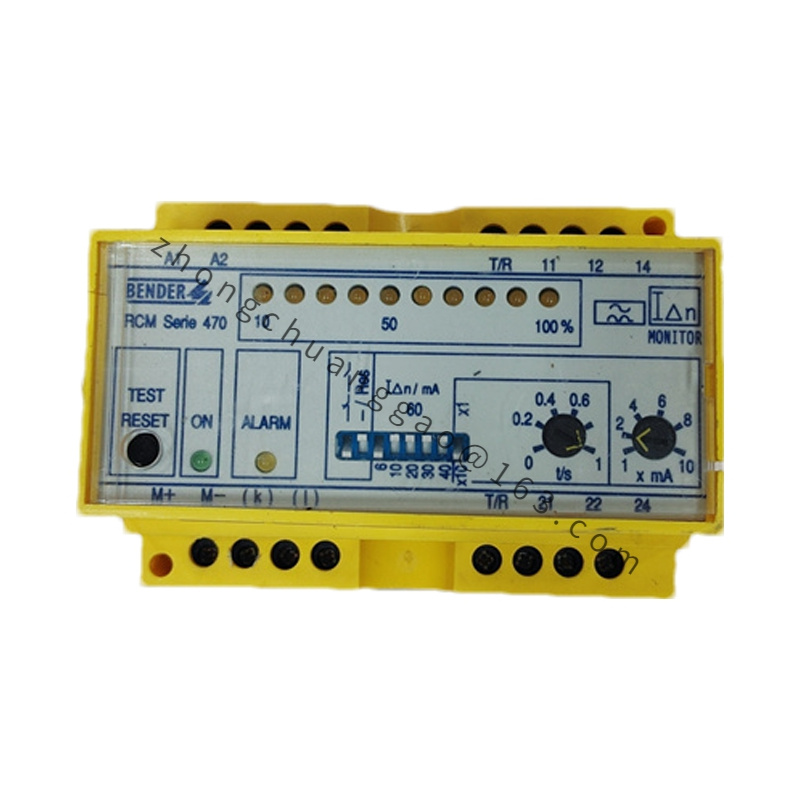

- Display and Controls:

- LCD Display: Provides real-time monitoring data and system status.

- Controls: Includes buttons for configuration and system management.

- Dimensions:

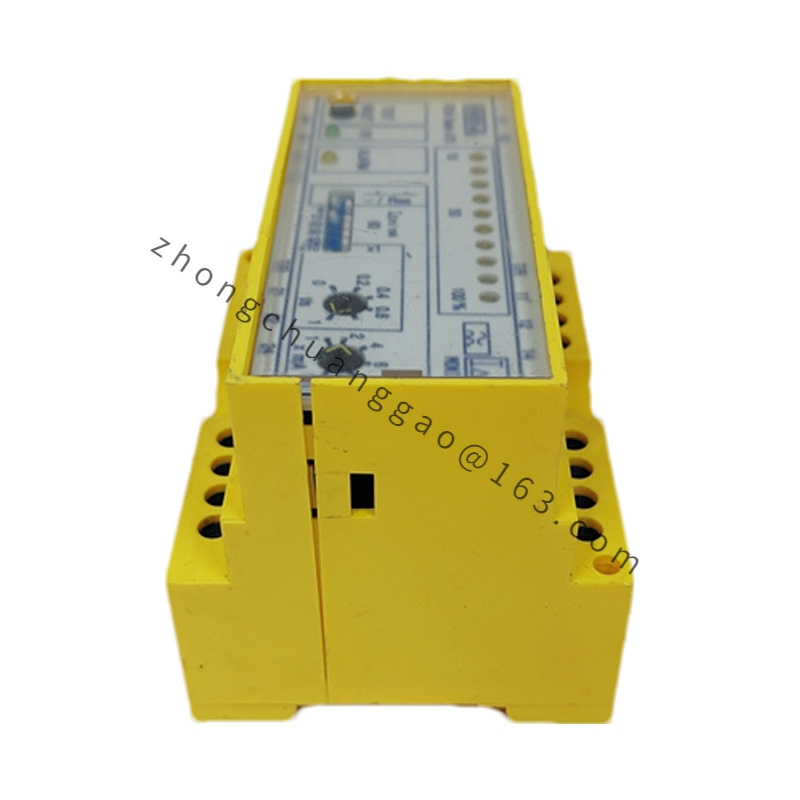

- Designed for compact installation in standard control panels.

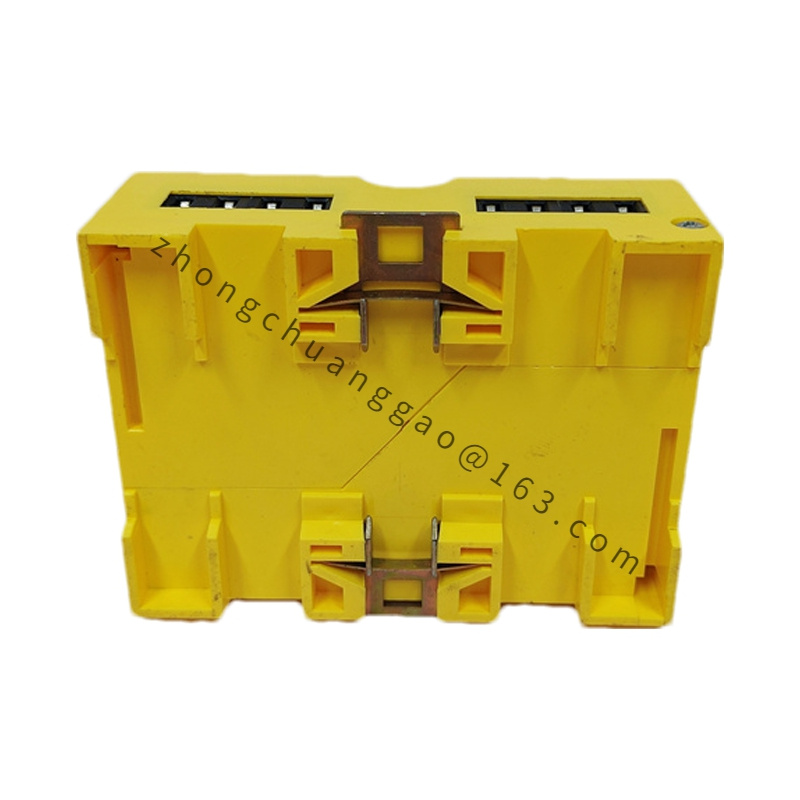

- Mounting: DIN rail mountable for easy integration into existing panels.

Functional Features

- High Precision Measurement:

- Provides accurate and reliable measurements of insulation resistance and leakage currents.

- Ensures early detection of potential issues to prevent system failures.

- Smart Diagnostics:

- Advanced diagnostic capabilities for identifying and analyzing faults.

- Offers insights into system performance and potential risks.

- Alarm and Warning:

- Configurable alarm thresholds for insulation resistance and leakage current.

- Provides visual and relay-based alarms to signal faults and trigger corrective actions.

- Flexible Configuration:

- Configurable parameters through the device’s interface or software tools.

- Allows customization of settings to match specific system requirements.

- Communication Integration:

- Supports integration with building management systems or other control systems via communication protocols.

- Facilitates remote monitoring and management.

Application Scenarios

- Industrial Automation:

- Used in industrial environments to monitor and ensure the safety of electrical installations and machinery.

- Protects against electrical faults that could lead to equipment damage or safety hazards.

- Building Management Systems:

- Suitable for integration into building management systems to monitor the integrity of electrical systems and prevent potential failures.

- Enhances safety and operational reliability in commercial and residential buildings.

- Energy Management:

- Applied in energy management systems to ensure the reliable operation of electrical infrastructure.

- Helps in maintaining energy efficiency and reducing downtime due to electrical faults.

- Critical Infrastructure:

- Utilized in critical infrastructure sectors such as healthcare, data centers, and transportation where electrical system reliability is crucial.

- Provides proactive fault detection to safeguard operations.

Additional Considerations

- Installation: Ensure proper installation according to the manufacturer’s guidelines to maintain optimal performance.

- Maintenance: Regularly check and calibrate the device to ensure accuracy and reliability over time.

- Support: For detailed technical support, installation guides, and troubleshooting, contact Bender or an authorized distributor.

.jpg)

-1.jpg)