Detailed content

1、 Technical specifications

High precision acquisition:

Resolution: Supports 24 bit resolution.

Accuracy: ± 0.05% accuracy, meeting the application requirements for high signal accuracy.

Multiple input signal types:

Supports input of various analog signals such as voltage, current, temperature, pressure, and flow rate.

The input range can be configured according to different signal types, such as 0-10V, 0-20mA, PT100, K-type thermocouple, etc.

Multiple control modes:

Supports multiple control modes such as speed mode, position mode, torque mode, etc., which can be selected and configured according to actual needs.

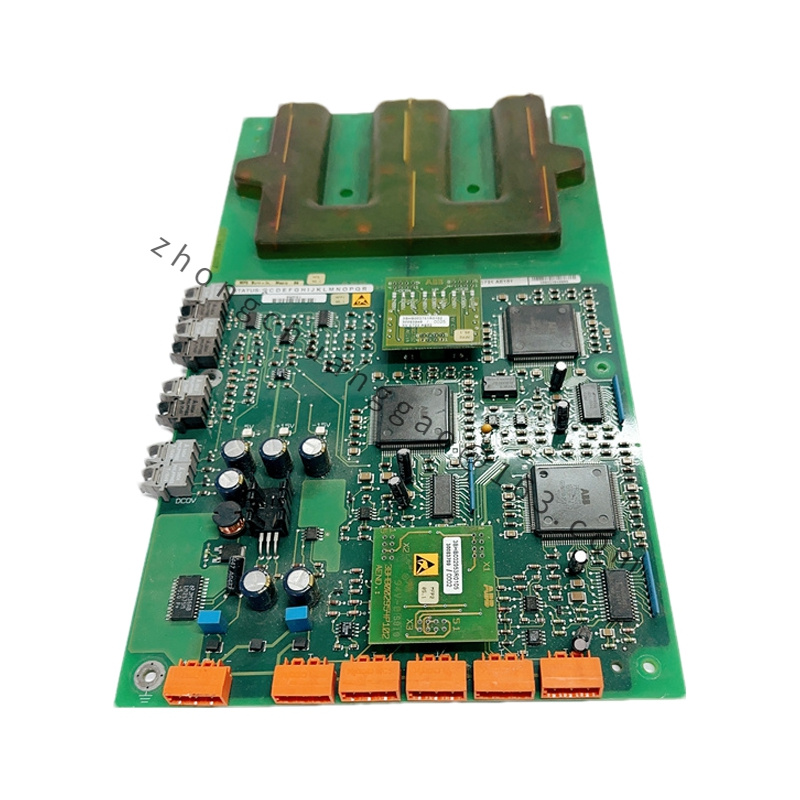

High speed data transmission:

Using high-speed communication interfaces such as RS485, Ethernet, Modbus, Profibus DP, EtherNet/IP, etc., to achieve fast data transmission and real-time response of control signals.

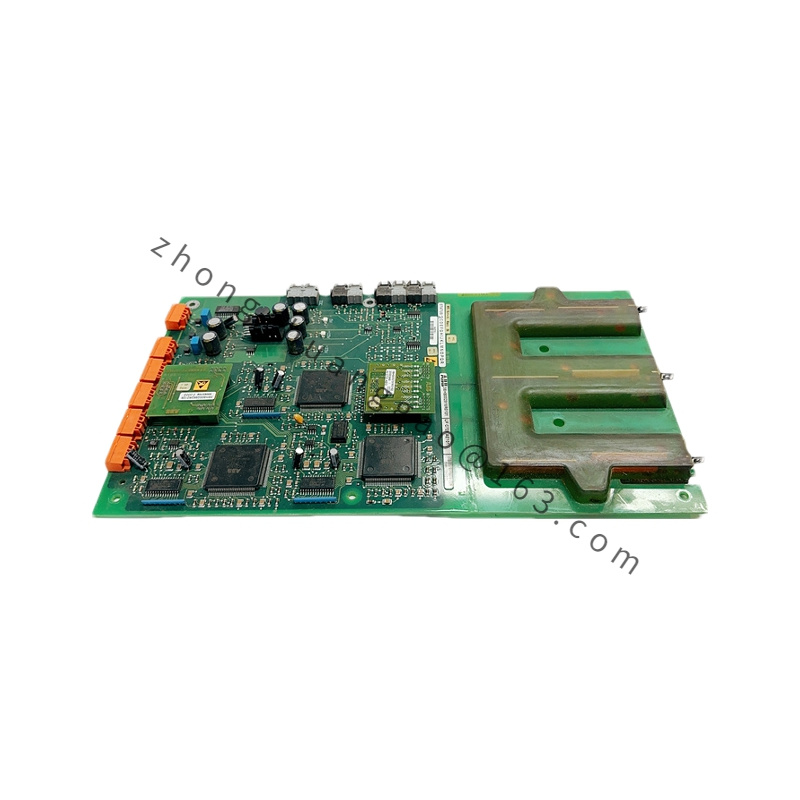

High integration:

Integrated with driver, control, and communication functions, simplifying system design and maintenance.

Processor and Memory:

Adopting high-performance processors with fast data processing and response capabilities.

Equipped with large capacity storage, it can store a large amount of data and programs, supporting complex application logic and algorithms.

2、 Functional Features

High precision control:

By using high-precision current and speed control algorithms, precise position and speed control of servo motors can be achieved.

High reliability:

Using high-quality electronic components and materials, rigorous testing and verification ensure stable operation in various harsh industrial environments.

Easy to configure and maintain:

Provide a simple and easy-to-use configuration interface and user-friendly operation method, making it convenient for users to configure parameters, monitor, and troubleshoot.

Supporting remote monitoring and maintenance functions reduces maintenance costs.

Programmability:

Supports multiple programming languages and development environments, allowing for custom programming and flexible application development to meet the needs of different application scenarios.

Scalability:

Supports multiple extension options and interfaces, and can add additional input/output modules and expansion cards as needed.

3、 Application scenarios

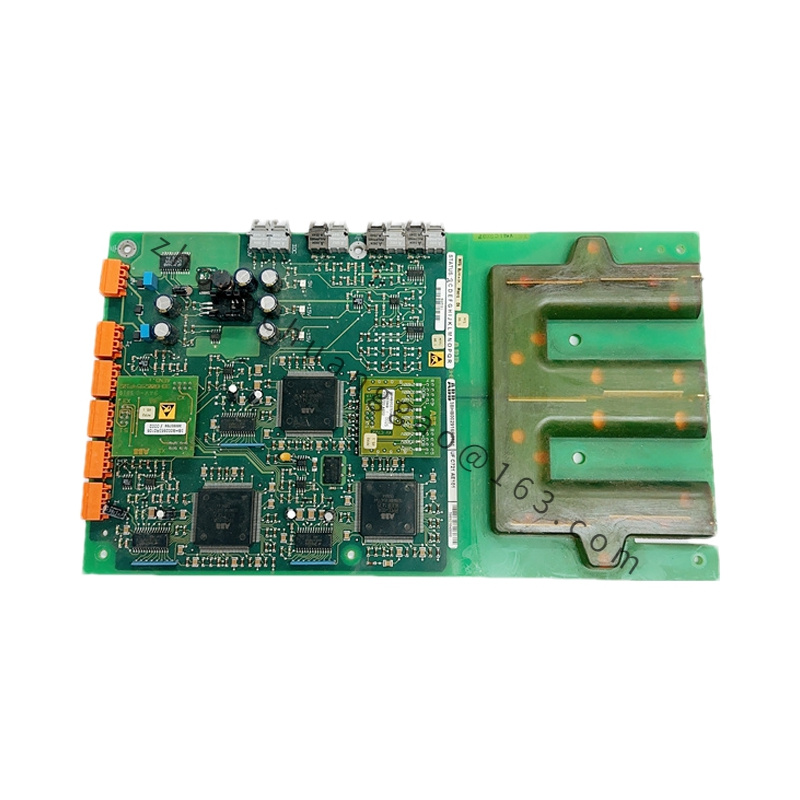

ABB UFC721AE101 3BHB002916R0101 servo drive module is commonly used in industrial automation and control systems, with specific application scenarios including but not limited to:

Servo motor control:

Control the operation and position of servo motors, including precise speed control, position control, and torque control.

High precision position control:

Suitable for applications that require high-precision position control, such as robots, CNC machine tools, automated production lines, etc.

Speed regulation and variable speed applications:

Realize the operation of servo motors at different speeds, suitable for various speed regulation and variable speed application scenarios.

Acceleration and deceleration control:

Control the acceleration and deceleration of the servo motor to achieve smooth start stop and reduce the impact and loss on the equipment.

Closed loop control system:

Usually equipped with feedback devices (such as encoders or Hall sensors) for real-time monitoring of the position and speed of servo motors, and closed-loop control based on feedback information.

.jpg)