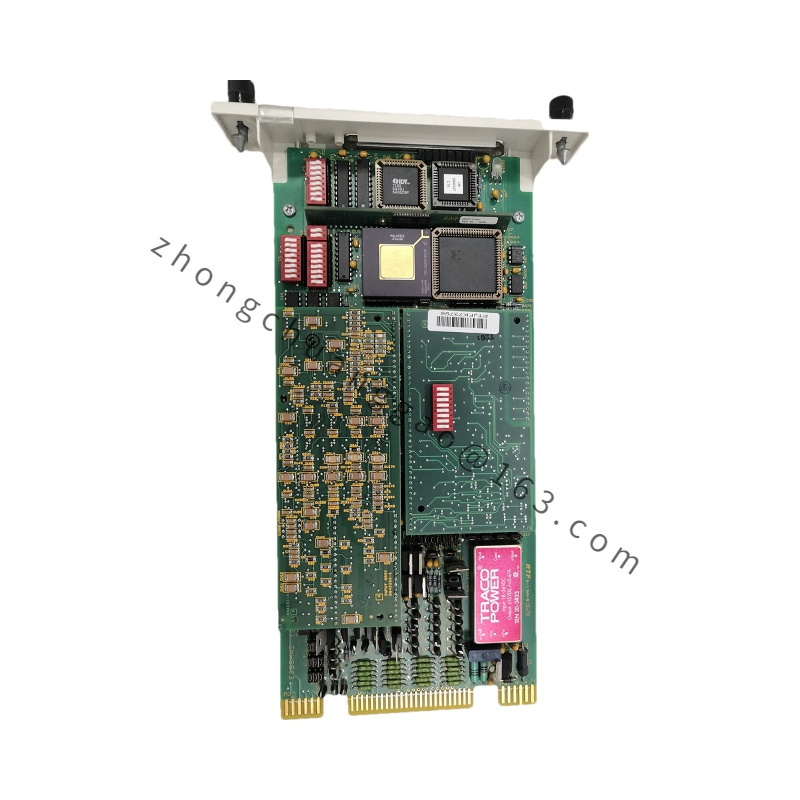

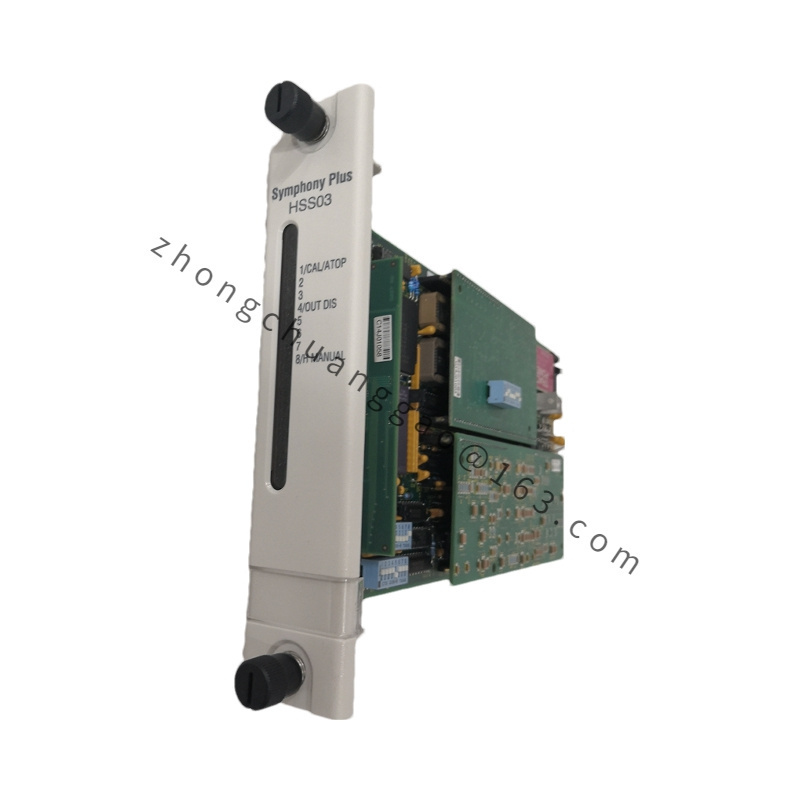

ABB SPHSS03

Technical Specifications:

Unfortunately, specific technical specifications such as exact voltage ratings, current consumption, or physical dimensions for the ABB SPHSS03 are not directly provided in the available sources. However, it is generally known that ABB products are designed to meet high industrial standards and offer precision performance.

Detailed content

Functional Characteristics :

High-Precision Control: The ABB SPHSS03 exhibits high-precision control capabilities, allowing for accurate control of hydraulic system outputs and parameters such as pressure, flow, and position.

Fast Response: It boasts a fast response speed, enabling dynamic control of the system within a short period of time, crucial for real-time adjustments.

Multi-Axis/Channel Control: Depending on the model and configuration, the SPHSS03 may support multi-axis or multi-channel control, allowing for simultaneous control of multiple hydraulic actuators or execution elements.

Closed-Loop Control: It employs a closed-loop control system that utilizes feedback signals for real-time adjustments, enhancing system accuracy and stability.

Programmability: The module is programmable, enabling users to customize control strategies and set parameters based on specific application requirements.

Stability: High-quality construction ensures stable operation under various conditions, making it suitable for demanding industrial applications.

Self-Diagnosis Function: Advanced versions may include self-diagnosis capabilities, detecting faults and providing alerts for prompt maintenance.

Remote Monitoring and Control: Through network connectivity, some models can be remotely monitored and controlled, enhancing operational efficiency.

Communication Interfaces: The SPHSS03 typically supports various communication interfaces like Ethernet, Modbus, CAN, etc., facilitating seamless integration with other control systems.

Safety Features: Incorporates safety features such as overload protection, overheating protection, and current limiting to safeguard equipment and systems.

Application Scenarios :

The ABB SPHSS03 hydraulic servo module finds widespread application in various industries, including but not limited to:

Machine Tools and Metal Processing: Used to control CNC machines and other metalworking equipment for precise motion control of tools and worktables.

Plastics Forming Machinery: In injection molding and extrusion machines, it precisely controls mold movements, injection, and extrusion processes.

Printing and Packaging: Controls printing rollers, paper cutters, and other motion systems in printing presses and packaging machines.

Material Handling and Logistics: Controls conveyor belts, elevators, and other material handling equipment for efficient logistics operations.

Automotive Manufacturing: Utilized in automotive production lines to control welding robots, assembly lines, and testing equipment.

Aerospace: Controls landing gear, actuators, and other motion systems in aircraft and spacecraft.

Metallurgy and Steel Production: Used to control the motion of rolling mills, furnace arrangements, and other metallurgical equipment.

Energy Production: In power plants, it controls valves, turbines, and other energy-related equipment.

Construction and Mining Machinery: Controls the motion of excavators, loaders, and other construction equipment.

Marine and Underwater Equipment: Used in ocean engineering and underwater robots to control mechanical arms and tools.

.jpg)

.jpg)