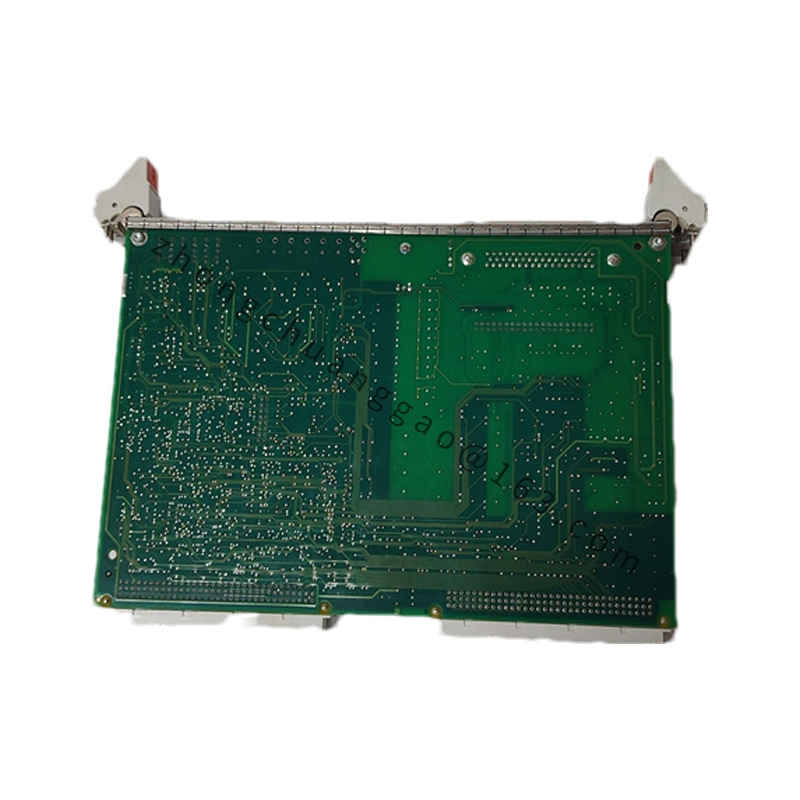

ABB PFSK152 3BSE018877R1

Technical specifications

Model and number:

Model: PFSK152

Number: 3BSE018877R1

Communication protocol:

Supports MODBUS RTU protocol and can be used for programming and as a slave device in MODBUS RTU networks.

It may also support other communication protocols, such as ASCII, depending on the configuration and version

Detailed content

Power supply and interface:

Provide two communication ports, each providing 5V DC, allowing for the connection of more micro HMI panels without the need for additional power supply.

Each port is equipped with LED indicators to indicate when the port sends or receives data.

Scalability:

It has an integrated expansion port that can be connected to other modules to achieve system expansion.

2、 Functional characteristics

Signal processing capability:

PFSK152 3BSE018877R1 is a high-performance signal processor module designed specifically for industrial automation and control systems.

Capable of quickly and accurately processing various input signals, including analog and digital signals, and outputting corresponding processing results.

Users can use this module to perform signal filtering, amplification, conversion, and other operations to meet the requirements of the control system.

Modular design:

Adopting a modular design, it is easy to install and maintain.

Support control room installation and facilitate integration into existing control systems.

Integration and portability:

Featuring integrity, mobility, small size, and light weight, it is suitable for various industrial environments.

Compatibility and Scalability:

Can seamlessly connect with equipment and systems from other ABB companies, achieving data sharing and complementary functionality.

Supports multiple communication protocols and interfaces, facilitating system integration and expansion for users.

Programming flexibility:

Provide rich programming interfaces and tools, supporting multiple programming languages such as Ladder Logic, Structured Text, etc.

Users can flexibly program according to their control needs and implement various complex control logics.

3、 Application scenarios

Industrial automation:

Widely used in the field of industrial automation, such as production line monitoring, equipment status detection, safety systems, etc.

It can be connected to various sensors, actuators, and other devices to achieve signal acquisition, processing, and control.

Energy management:

In the energy management system, it is used to monitor and control the operating status and energy consumption of various energy equipment.

manufacturing

In the manufacturing industry, it is used to achieve real-time monitoring and control of the production process, improve production efficiency and product quality.

Building automation:

In building automation systems, it is used to control lighting, air conditioning, security and other equipment to improve the intelligence level of buildings.

.jpg)