Detailed content

1、 Technical specifications

Interface type: This module is usually equipped with multiple communication interfaces, such as Ethernet, serial port, Profibus, Modbus, etc., to meet the interconnection and interoperability requirements between different devices.

Data transmission capability: With high-speed data transmission capability, it can quickly transmit large amounts of data, ensuring real-time and efficiency.

Protocol support: Supports multiple communication protocols to adapt to the communication requirements of different devices or systems and achieve interoperability between devices.

2、 Functional characteristics

Multiple communication interfaces: The configuration of multiple interfaces enables the module to easily connect different types of devices, improving the integration and intelligence level of the system.

High reliability: Using high-quality electronic components and materials, rigorously tested and validated to ensure stable operation in various harsh industrial environments, with high reliability and long lifespan. At the same time, the module also has fault diagnosis and alarm functions, which can detect and locate faults in a timely manner, improving the reliability and stability of the system.

Easy to configure and maintain: Provides a simple and user-friendly configuration interface and user-friendly operation mode, making it convenient for users to configure parameters, monitor, and troubleshoot. In addition, it also supports remote monitoring and maintenance functions, which can easily connect and communicate with the upper computer or industrial network.

Good compatibility: This module has good compatibility and can be connected and integrated with various types of control systems such as PLC and DCS, making it convenient for users to upgrade and modify their systems. At the same time, it can also communicate and exchange information with devices from other brands, improving the openness and interoperability of the system.

Programmability: Users can configure and customize according to their actual needs, flexibly adapting to different communication scenarios.

Support redundancy: In order to improve the reliability of the system, some communication modules may support redundant configuration to achieve device backup and fault switching, ensuring the continuous and stable operation of the system.

3、 Application scenarios

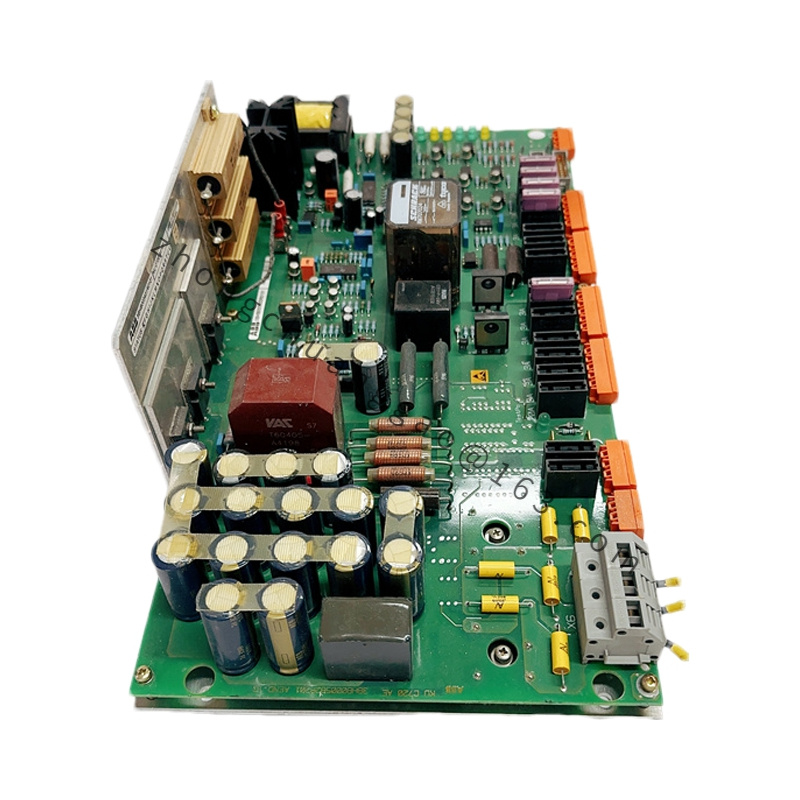

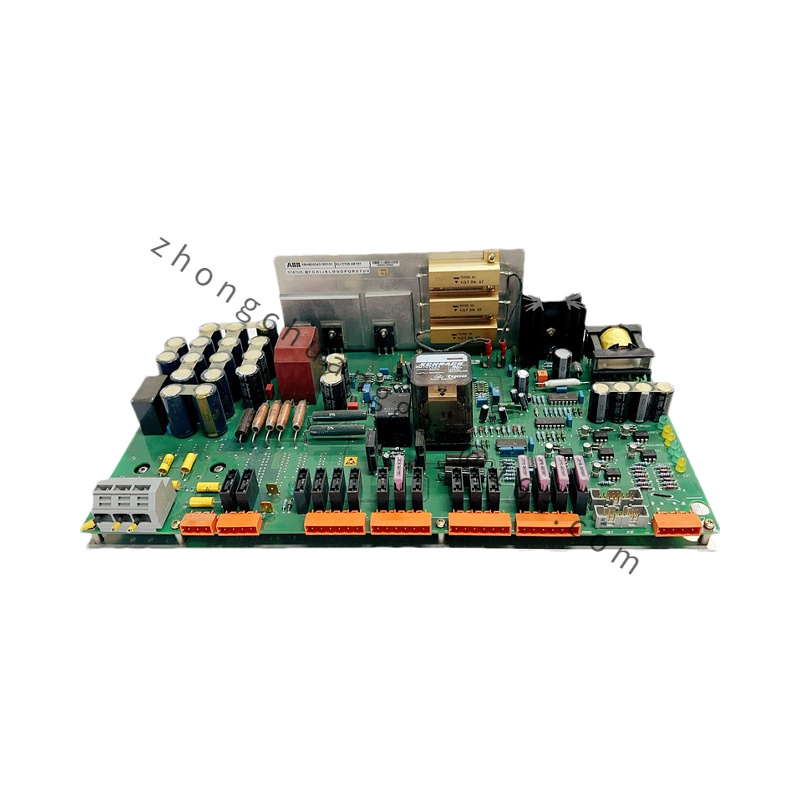

The ABB KUC720AE01 3BHB003431R0101 communication module is widely used in the field of industrial automation, including but not limited to the following scenarios:

Production line automation: In automated production lines, this module can achieve data communication and coordinated control between different devices, improving production efficiency and product quality.

Process Control System: In process control systems in industries such as chemical, petroleum, and metallurgy, this module can be used to achieve data transmission and instruction execution between various sensors, actuators, and control systems.

Intelligent Building: In the field of intelligent buildings, this module can be used to achieve functions such as equipment monitoring, energy management, and safety control in building automation systems.