Detailed content

Input frequency up to 10 kHz

Resolution up to 23 bits

Power supply voltage 24 VDC

Power consumption 5W

Working temperature -20 ° C to+60 ° C

Storage temperature -40 ° C to+85 ° C

Shell protection level IP20

Dimensions 110mm x 60mm x 25mm

System compatibility is part of the ABB AC800M I/O system

2、 Functional Features

High precision measurement: By supporting a resolution of up to 23 bits, the DSDP150 57160001-GF can achieve high-precision position measurement, suitable for applications that require high position accuracy.

Multiple encoder types are supported: incremental, absolute, and servo motor encoders are supported, providing users with more flexible configuration options.

High input frequency: With an input frequency of up to 10 kHz, it is capable of processing rapidly changing position signals and is suitable for high-speed motion control applications.

Stable and reliable: Designed to be sturdy and capable of stable operation in harsh industrial environments, while also having a wide operating temperature range to adapt to different application environments.

Easy to integrate: As part of the ABB AC800M I/O system, the DSDP150 57160001-GF can be easily integrated into existing automation systems, reducing system integration costs and time.

3、 Application scenarios

DSDP150 57160001-GF is widely used in the following fields due to its high precision, high reliability, and support for multiple encoder types:

Industrial automation: Used in industrial automation production lines to precisely control the position, speed, and acceleration of robots, improving production efficiency and product quality.

Machine tool processing: In CNC machine tools, it is used to achieve precise machining path control and position feedback, ensuring machining accuracy and quality.

Material handling: In automated material handling systems, such as automated warehouses and conveyor lines, it is used to achieve precise positioning and tracking of materials.

Packaging machinery: In packaging machinery, it is used to control the cutting, sealing, and stacking of packaging materials to ensure packaging quality and efficiency.

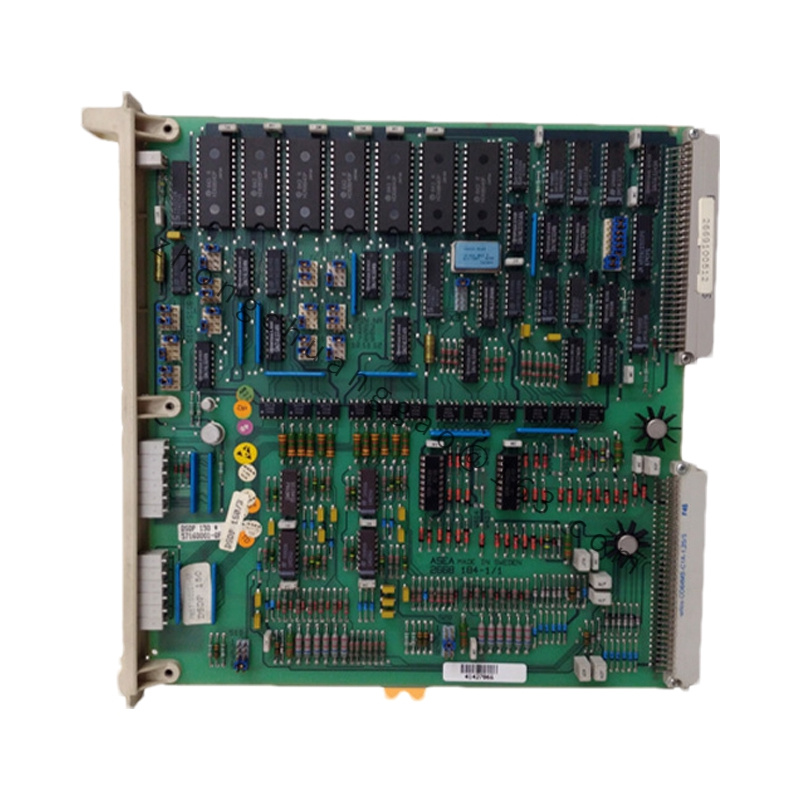

.jpg)

.jpg)

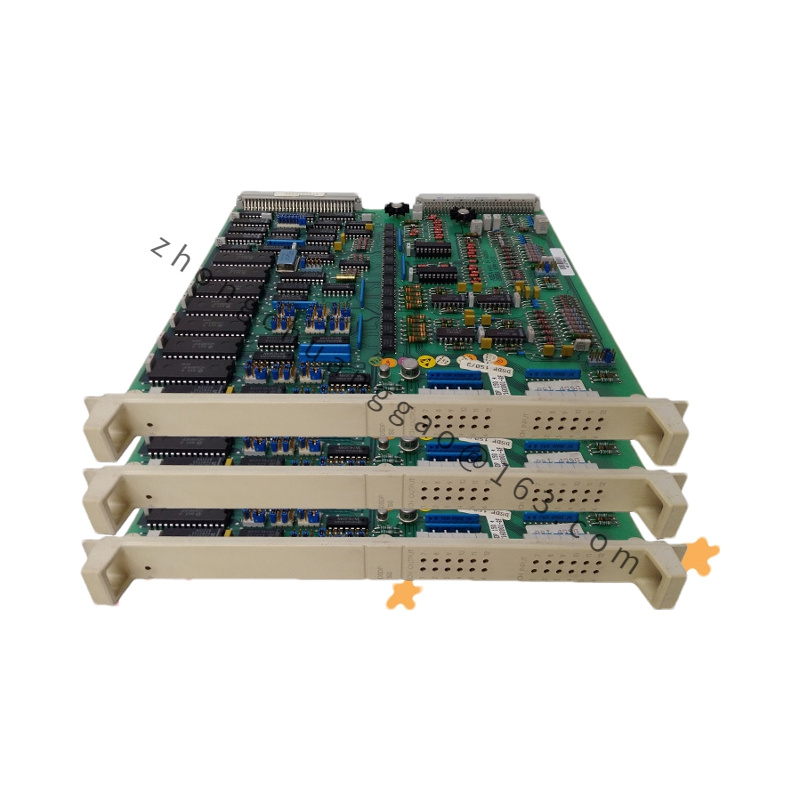

.jpg)