Detailed content

1、 Technical specifications

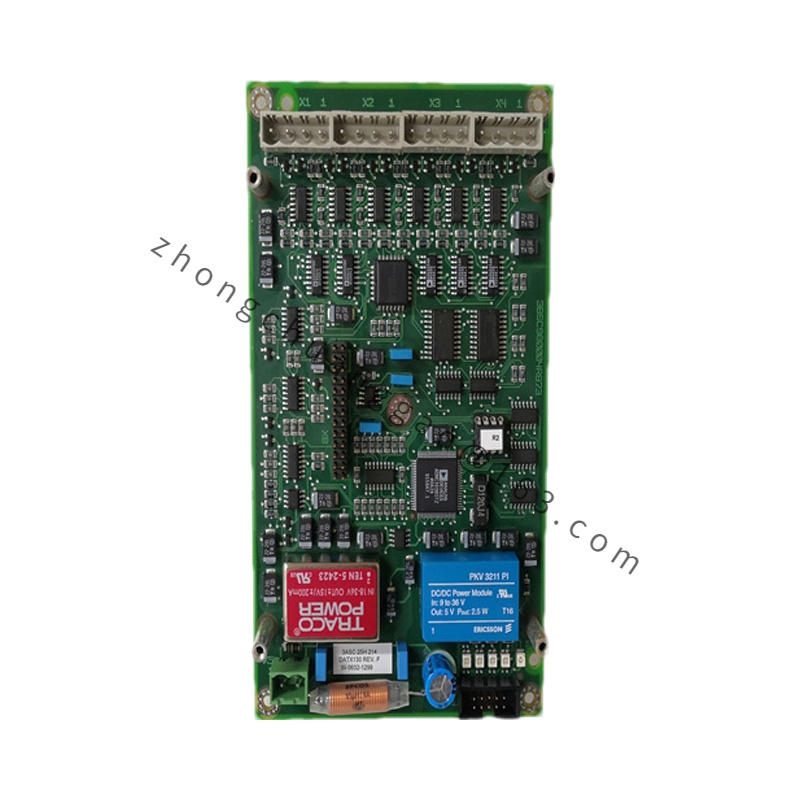

Model: ABB DATX130 3ASC25H214

Function: Used to obtain feedback information such as rotor position and speed from rotating equipment

Accuracy: Equipped with high-precision sensors to ensure accurate position and velocity measurements

Signal processing: With signal processing function, it can convert analog signals obtained from sensors into digital signals for use by control systems

Communication interface: Supports various digital communication protocols, including Modbus RTU, Modbus TCP/IP, and Ethernet/IP, allowing data exchange with other control system components

Size and installation: The size and installation method of the board may be suitable for specific types of equipment or systems, and the specific size needs to refer to the product manual

Temperature range: Due to the frequent operation of industrial equipment under different temperature conditions, this board can operate within a certain temperature range. The specific range needs to be consulted in the product specifications

2、 Functional characteristics

High precision measurement: Using high-precision sensors, it can accurately measure the rotor position and speed of rotating equipment, providing precise data support for the control system.

Strong signal processing capability: Equipped with built-in signal processing function, it can convert analog signals into digital signals in real time, making it easy for the control system to process and analyze data.

Rich communication interfaces: supporting multiple digital communication protocols, enabling easy data exchange with other control system components, achieving comprehensive control and management.

Strong compatibility: It can be used in conjunction with various types of torsion sensors (such as Hall sensors, photoelectric sensors, and electromagnetic sensors) to meet the needs of different application scenarios.

Easy to integrate: It can be integrated with other automation equipment and control systems to achieve real-time monitoring and control of the rotor position and operation of the equipment, improving the overall performance and reliability of the equipment.

3、 Application scenarios

ABB DATX130 3ASC25H214 rotor feedback board is widely used in various industrial automation systems, especially when monitoring and controlling the operation of twisting equipment. Specific application scenarios include but are not limited to:

Motor control: used to monitor and control the rotor position and speed of the motor, ensuring stable operation and efficient operation of the motor.

Generator control: In the power generation system, monitoring and controlling the rotor position and speed of the generator, optimizing power generation efficiency, and ensuring the stable operation of the power grid.

Wind turbine control: In the field of wind power generation, monitoring the rotor position and speed of wind turbines can improve the efficiency and stability of wind power generation.

Mechanical manufacturing: In the process of mechanical manufacturing, it is used to monitor and control the rotor position and speed of mechanical equipment, ensuring the smooth progress of the production process and the stability of product quality.

Process control: In the production process of chemical, metallurgical and other industries, monitoring and controlling the rotor position and speed of key equipment to ensure the safety and stability of the production process.

.jpg)