Detailed content

Technical Specifications

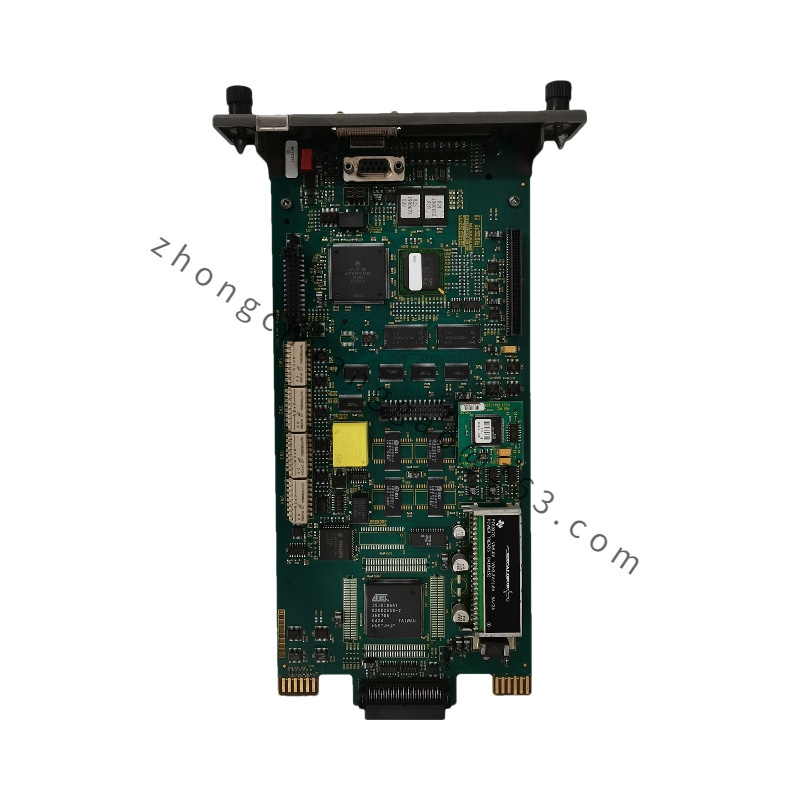

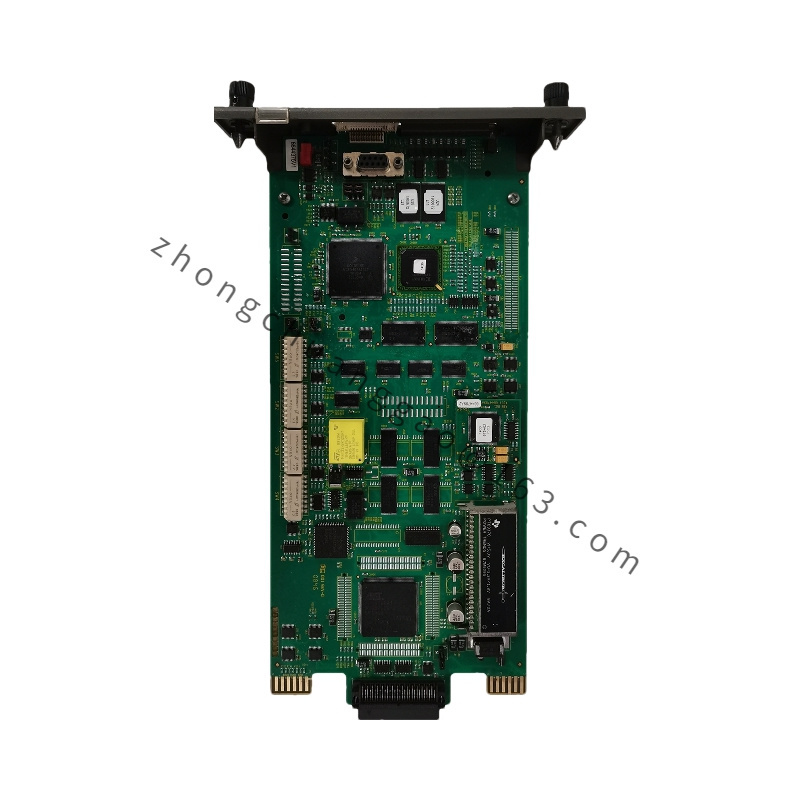

Microprocessor: 32-bit industrial microprocessor with advanced capabilities.

Memory:

ROM: Typically includes Flash ROM for program storage.

SDRAM: High-capacity SDRAM for efficient data processing.

NVRAM: Non-volatile RAM for storing critical data during power loss.

Specific Numbers (as per some sources):

ROM: 2 Mbytes Flash ROM

SDRAM: 8 Mbytes

NVRAM: 512 kbytes

CPU Speed: High-speed processing capabilities, enabling real-time control and data processing.

Specific Speed (as per some sources): 160MHz RISC industrial-grade chip.

Power Requirements:

+5VDC with specific current requirements for typical operation.

Specific Power Requirements (as per some sources):

+5VDC/2A 10W (typical)

+5VDC/100mA 0.5W (typical)

I/O Capabilities:

Supports analog and digital I/O signals, including high/low-level analog signals, temperature signals (TC, RTD), pulses, frequencies, and digital signals.

Specific I/O Details (as per some sources):

Multiple analog outputs configurable for voltage or current signals.

Multiple digital inputs and outputs with high input frequency capabilities.

Functional Features

High Processing Power: Equipped with a powerful 32-bit microprocessor and ample memory, ensuring fast and efficient control.

Redundancy Support: Offers redundant controller configurations for increased system reliability and availability.

Multi-tasking Capability: Enables simultaneous execution of multiple control strategies with different scan periods.

Programmability: Supports various programming languages and environments, including functional codes, C, Basic, Batch, Ladder, and user-defined languages.

Compatibility: Fully compatible with ABB’s Symphony control system and other relevant ABB systems, ensuring seamless integration.

Online Configuration: Allows modifications and additions to controller configurations without interrupting the control process.

Fault Tolerance: Equipped with fault detection and handling mechanisms to ensure continuous operation even in the face of faults.

Application Scenarios

Process Control: Ideal for complex process control applications, where precise monitoring and control of various process variables are crucial.

Industrial Automation: Widely used in industrial automation systems for controlling machines, equipment, and processes.

Power Generation: Deployed in power plants for controlling critical equipment and processes, ensuring stable and efficient power generation.

Manufacturing: Found in manufacturing facilities for automating production lines, reducing downtime, and improving overall efficiency.

Oil and Gas: Utilized in oil and gas industries for controlling equipment and processes in drilling, refining, and distribution.

.jpg)